Products

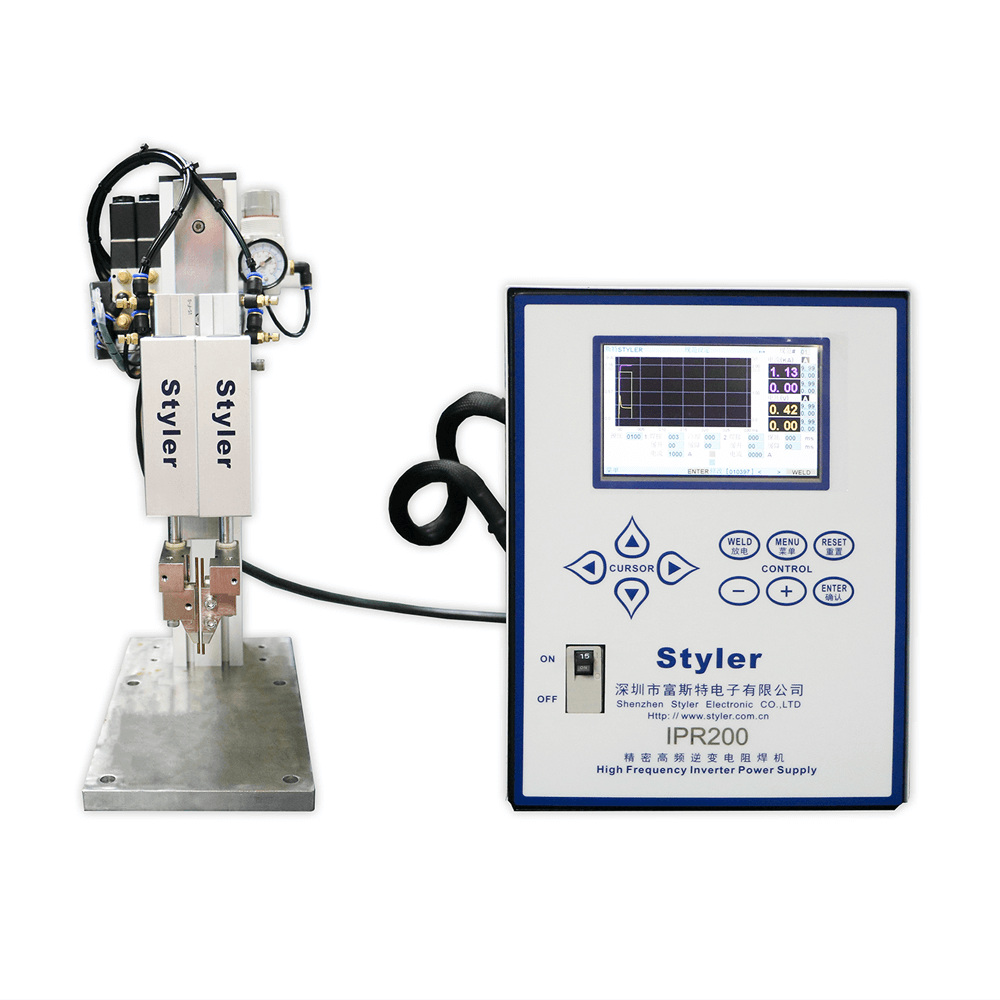

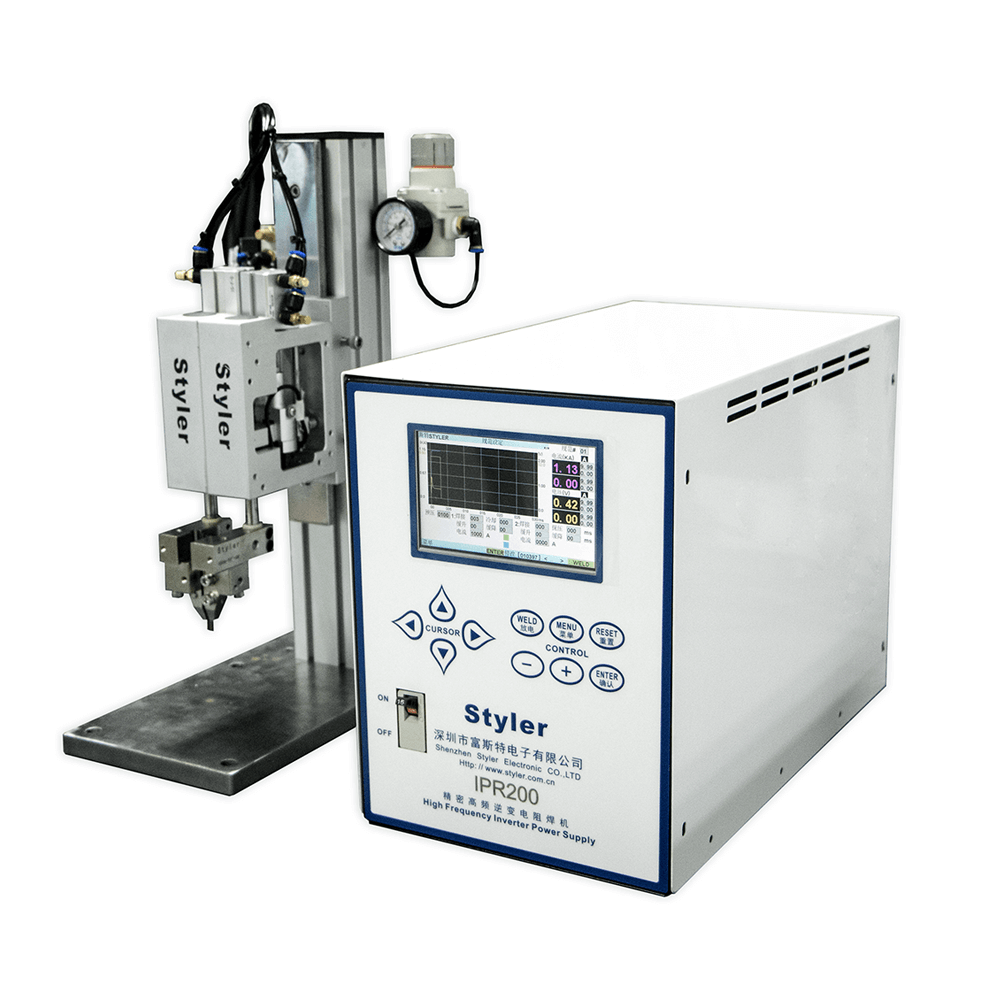

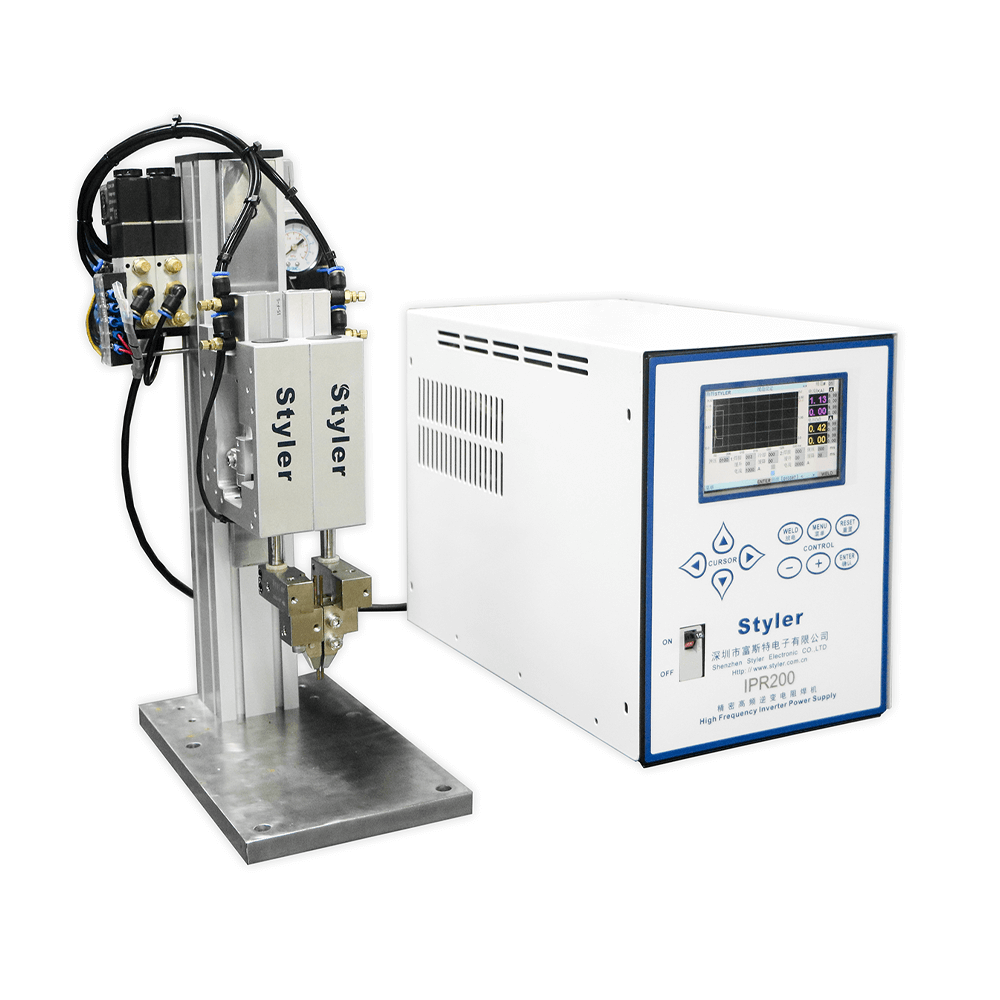

IPV200 Resistance Welding Machine

Product Features

Yekutanga inogara iripo kutonga, inogara voltage control, yakasanganiswa kutonga, kuve nechokwadi chekusiyana kwewelding. High control rate: 4KHz.

Kusvikira makumi mashanu akachengetwa welding mapatani ndangariro, kubata akasiyana workpiece.

Zvishoma welding spray kune yakachena uye yakanaka welding mhedzisiro.

Kuvimbika kwepamusoro uye kushanda kwepamusoro.

Product Details

Parameter hunhu

| MO DEL | IPV100 | IPV200 | IPV300 | IPV500 |

| ELEC TRICAL PARAMETERS | max curr:1500A | max curr:2500A | max curr:3500A | max curr:5000A |

| ELEC TRICAL PARAMETERS | no-load volt: 7 .2V | hapana-mutoro volt: 8.5V | hapana-mutoro volt 9 | hapana-mutoro volt: 10V |

| kuisa: 3 chikamu 340 ~ 420VAC 50/60Hz | ||||

| RATED CPACITY OF TRANSFORMER | 3.5KVA | 5.5KVA | 8.5KVA | 15KVA |

| ZVIDONGO | kunyanya const curr, const . Volt , yakasanganiswa contro volt: 00.0% ~ 99 .9% | |||

| KUDZORA KUNYORERA | curr:200~1500A | curr:400~2500A | curr:400~3500A | curr:800~5000A |

| kunonoka kusimuka 1, kunonoka kusimuka 2:00 ~ 49ms | ||||

| welding nguva 1:00 ~ 99ms;welding nguva 2:000 ~ 299ms | ||||

| kunonoka nguva 1; kunonoka nguva 2:00 ~ 49ms | ||||

| yakaonekwa peak curr kukosha: 0-8000 | ||||

| KUITA NGUVA | kumanikidzwa kuonana nguva: 0000 ~ 9999ms | |||

| welding danda kutonhora nguva: 000 ~ 999ms | ||||

| kubata nguva mushure mekucheka: 000 ~ 999ms | ||||

| NZIRA YEKUPODZA | mhepo | |||

| EX.SIZE | 215(W)X431( D)X274(H)mm | |||

| KUPAKA SIZE | 280(W)X530( D)X340(H)mm | |||

| GW | 17KG | 23KG | ||

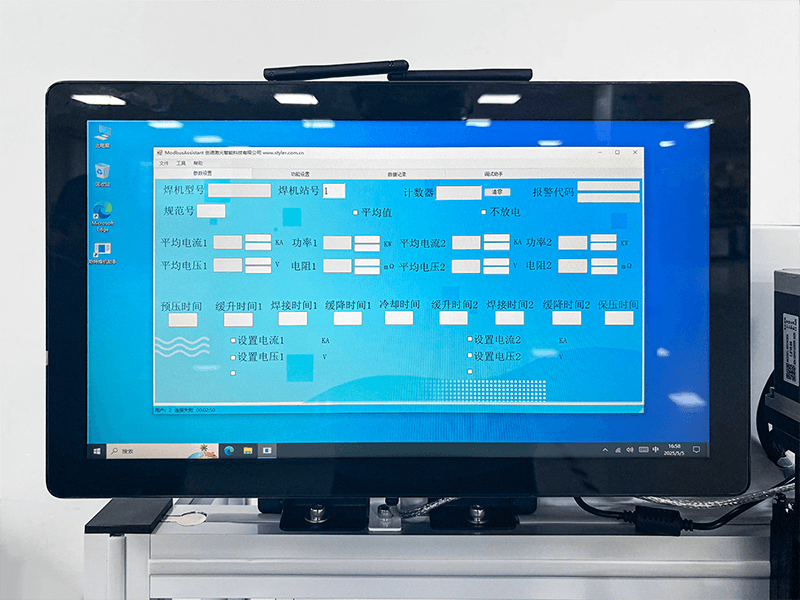

Optional accessories

Kombuta (chaiyo-nguva yekutarisisa yemajoini ekutengesa, data inogona kutumirwa kuburikidza neRS485)

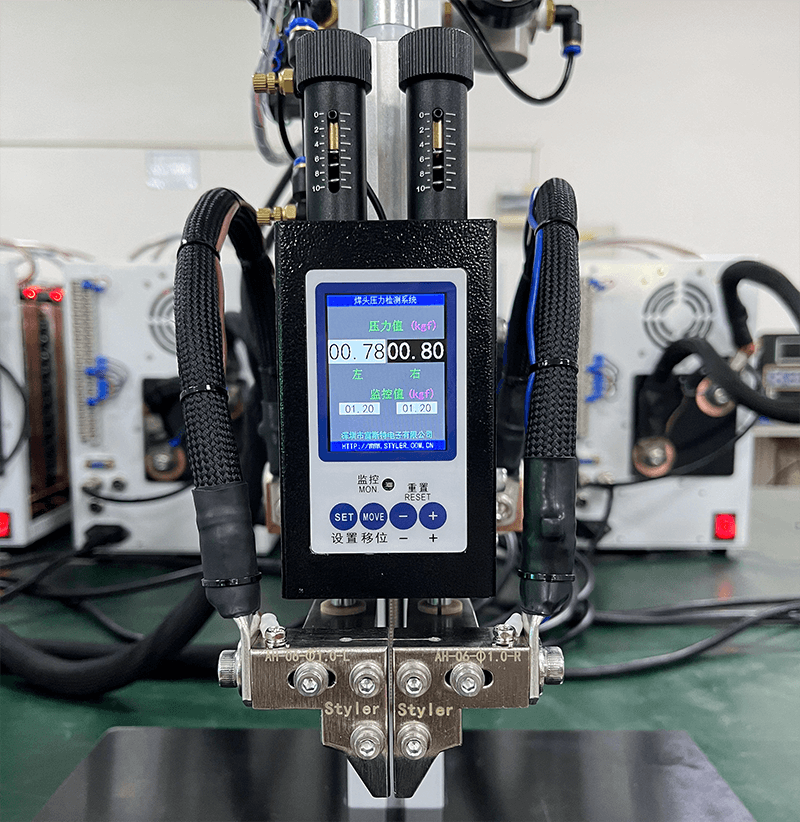

Wedzera kudzvanya sensor kune welding musoro (kudzvanywa kwezvisungo pamativi ese maviri kunogona kugadzikwa kuve kunoenderana, uye kudzvanywa panguva yewelding kunogona kutariswa)

Sei Tisarudze

-Tinotsigira OEM kana ODM?

-Ko iyo yekutanga R&D yekugadzira pendi ine mutengo mukana?

-Uri zvigadzirwa zvemhando yepamusoro zvigadzirwa here?

-Tine timu yakanaka here?

-Chigadzirwa chedu chinotsigira pasi rese mushure mekutengesa sevhisi here?

-Chigadzirwa chedu chakasimbiswa here?

mhinduro yese inoti "HONGU"

Yakakurumbira Sayenzi Knowledge

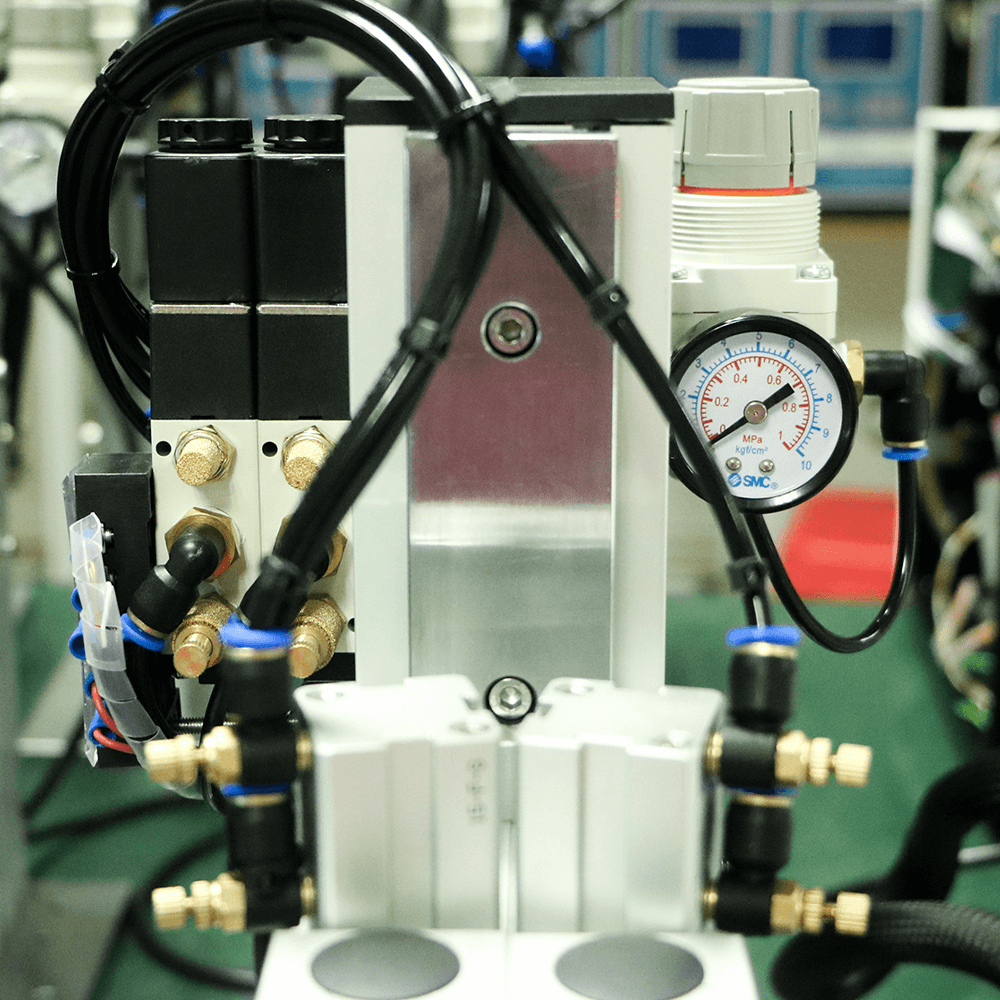

Iyi pneumatic spot welding muchina unonyanya kushandiswa 18650 cylinder call pack welding, inogona weld Nickel tab ukobvu kubva 0.02-0.2 mm ine yakanaka welding mhedzisiro.

Iyo Pneumatic modhi ine vhoriyamu diki uye huremu, iri nyore kutumirwa kune dzimwe nyika.

Sinlge point tsono inogona kushandiswa kuNi tab weld ine Stainless simbi kesi.

1. Microcomputer control, CNC ikozvino kugadzirisa.

2. High precision welding simba.

3. Digital chubhu kuratidza, keyboard control, welding parameters flash storage.

4. Double pulse welding, ita kuti welding iwedzere kusimba.

5. Small welding sparks, solder joint yunifomu chitarisiko, pamusoro yakachena.

6. Welding nguva dzinogona kuiswa.

7. Inogona kuisa preloading nguva, nguva yekubata, nguva yekuzorora, welding speed inogona kugadziriswa.

8. Simba guru, rakagadzikana uye rakavimbika.

9. Kaviri tsono kudzvinyirirwa zvinochinjika zvakasiyana, Inokodzera siyana ukobvu yeNickel strip.