Munyika inokurumidza kushanduka yekugadzira mabhatiri-kupa simba zvese kubva kuEVs kusvika kune zvemagetsi zvevatengi uye grid kuchengetedza-welding inomira seyakakosha, asi kazhinji inonetsa, maitiro ekusangana kwebhatiri pack. Kutendeseka kwese kubatana kunobata zvakananga kuchengetedzeka kwepakiti, kuita, uye hupenyu hurefu. Pa STYLER, isu tinonyanya kugadzira welding uye gungano mhinduro dzepack-level yekubatanidza, kusanganisira chaiyo Resistance.Spot Welders, Michina yeLaser Welding inomhanya zvikuru, uye turnkey Battery Module & Pack Assembly Lines.

We'takanyora mibvunzo gumi inowanzoitika inosangana nechikwata chedu cheinjiniya maererano nebhatiri pack welding, ichipa ruzivo rwenyanzvi kuti ikubatsire kufamba kuomarara kwayo.

1. Ndeipi yakanyanya kufanirwa welding process yekubatanidza cylindrical cell modules kana bhatiri pack busbars?

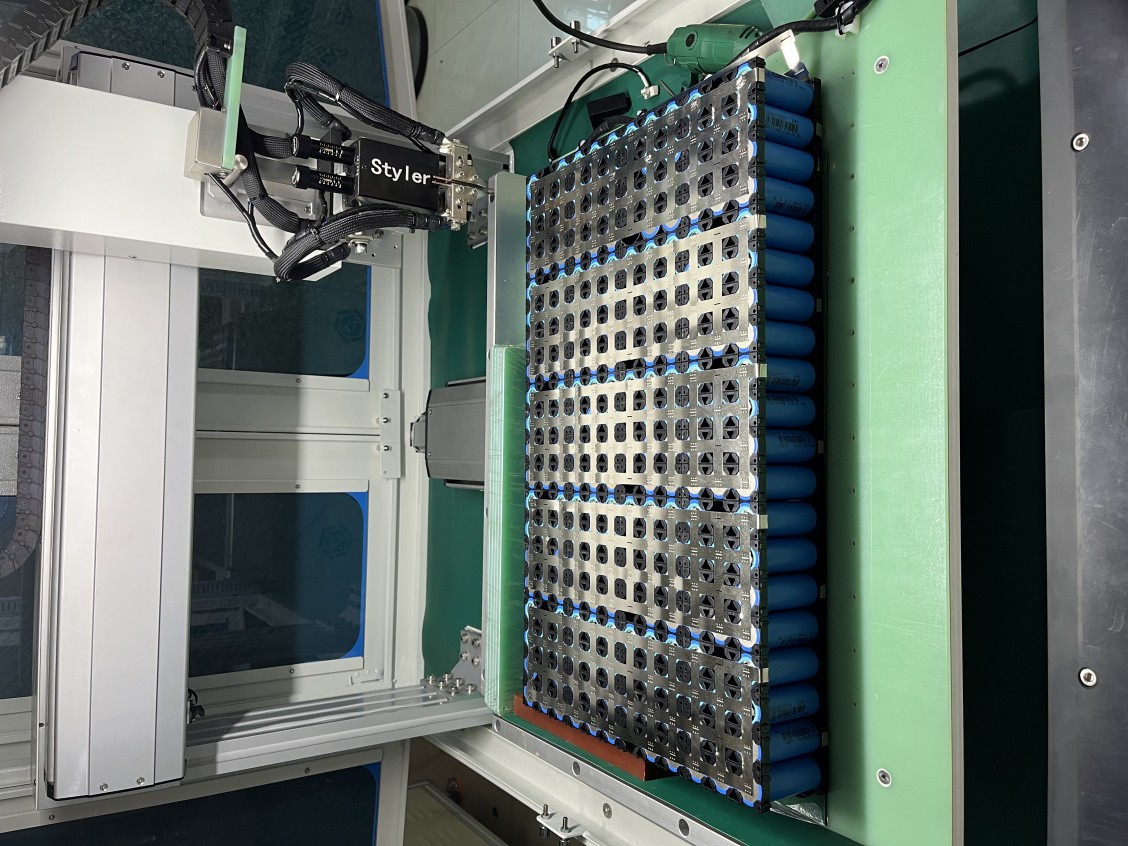

Zvekubatanidza maseru mumamodule kana kujoinha mabhazi mukati mepakeji, Resistance Spot Welding inowanzova sarudzo yakasarudzika. It'sa inokurumidza, inodhura, uye yakavimbika nzira yekugadzira akawanda akasimba emagetsi ekubatanidza. STYLER's spot welders, uchishandisa tekinoroji yetransistor yepamberi, unza kumhanya kwakasiyana uye kugadzikana, nemhinduro yazvino yazvino uye kudzora kunogadzirisa kubata zvinhu zvitete, zvinobata senge nickel-plated busbar.

2. Tinodzivirira sei kupisa uye kukuvara kwekupisa kune masero ebhatiri panguva yekutakura welding?

Thermal management panguva yekusangana kwepakiti yakakosha. Chinokosha kudzora kupinza kwesimba nehunyanzvi hwakanyanyisa panzvimbo dzekubatanidza. Yedu Transistor-based Resistance Spot Welders vanowana izvi kuburikidza ne-ultra-short, chaiyo nguva yewelding cycles (milliseconds), kuderedza kupisa kupararira. Kune laser welding, kusarudza iyo chaiyo paramita uye kushandisa yakakwirira-kumhanya galvanometer scanners inoisa kupisa kupinza. Masisitimu edu anogona kubatanidza kudziya kwekutarisa kuti ive nechokwadi chekuti masero ari padyo anoramba ari mukati memiganhu yakachengeteka.

3. Aluminium nemhangura-aluminium composites inowanikwa mumapakiti emabhasi. Ndeapi mawelding solutions?

Welding zvinhu izvi zvinoda kunyatsosarudzwa maitiro. Kune welding, yakachena nickel's high conductivity inoda yakakwira ikozvino munguva pfupi pfupi. STYLER's transistor welders inopa inodiwa nekukurumidza, yakagadzikana simba pulse. Kune laser welding yealuminium busbars uye yekubatanidza, inoshanda zvakanyanya. Nekudaro, kune chaiwo mabhazi emhangura mumusangano wepakeji, laser welding inopa matambudziko nekuda kwekutarisisa kwakanyanya uye kupisa kwemafuta. Imwe nzira inoshanda uye inokurudzirwa ndeye kushandisa copper-aluminium composite busbars (clad materials), uko laser weld inoitwa pane aruminiyamu layer, kuve nechokwadi chakavimbika uye chakasimba kubatana.

4. Kuchena kwezvinhu uye kugadzirira kwepamusoro kwepack welding kwakakosha sei?

Kutsoropodza zvakanyanya. Oxides, oiri, uye zvinosvibisa pamabhazi kana zviteshi zvinokonzeresa kusawirirana kwemhando yeweld, kuwedzera kwemagetsi kuramba, uye kutadza kutadza. A robust pack assembly process inofanira kusanganisira kucheneswa kwakaringana (semuenzaniso, kuchenesa laser, kuchenesa plasma) nekukurumidza usati wapinza. STYLER's Battery Pack Assembly Lines inogona kubatanidza otomatiki yekuchenesa zviteshi kuti ive nechokwadi chekuenderana pamusoro pemamiriro ekubatanidza kwese.

5. Tinoita sei kuti tive nechokwadi chekuenderana weld mhando mukugadzirwa kwepamusoro-vhoriyamu paki?

Consistency inobva pakugadzikana kwemidziyo, kuongorora maitiro, uye otomatiki. Michina yedu inosanganisira:

Real-time Process Monitoring: Kuyera dynamic kuramba (spot welding) kune yega weld.

Yakavharwa-Loop Adaptive Control: Kugadzirisa otomatiki maparamita zvichienderana nemhinduro.

100% Post-Weld Inspection: Kubatanidza masisitimu ekuona ekuiswa kweweld uye kuyedzwa kwemagetsi kuramba mumutsetse wegungano kuti uve nechokwadi chemhando.

6. Ndezvipi zvakakosha zvelaser welding mubhatiri pack assembly?

Laser Welding inopa yakasarudzika kuchinjika mu weld geometry (mitsetse, madenderedzwa, contours), kushoma mechanicha kusagadzikana, uye kugona weld munzvimbo dzakavharirwa mukati mepakeji chimiro. Yakanakira welding module end plates, cover seams (pazvinoshanda), uye yakaoma busbar maumbirwo. Iyo inoderedza kupfeka kwezvishandiso uye inogonesa yakakwirira-kumhanya, aesthetically yakachena seams.

7. Ndeipi iyo turnkey Battery Pack Assembly Line inodiwa vs. standalone welders?

Standalone welders akanakira R&D, mitsara yekutyaira, kana chaiwo sub-assembly matanho. A turnkey Battery Pack Assembly Line yakakosha pakubatanidzwa, yakakwirira-vhoriyamu kugadzirwa kwemamodule akazara kana mapaketi. STYLER inogadzira mitsara inogadzirisa kutevedzana kwese: module stacking, bhasibar kuiswa, welding (spot kana laser), magetsi ekuyedza, uye yekupedzisira kubatanidzwa. Izvi zvinowedzera kubuda, kuderedza kukanganisa kwevanhu, kunovimbisa kurongeka, uye kunogonesa nzvimbo yepasi.

8. Iwe unogadzirisa sei weld spatter mubhatiri pack, izvo zvinogona kukonzera mapfupi maseketi?

Spatter mukati mepakiti injodzi yakakomba yekuchengetedza. Munzvimbo welding, inodzorwa nekugadzirisa iyo weld pulse chimiro uye electrode simba. Yedu Transistor-yakavakirwa Spot Welders inopa yepamusoro pulse control, zvakanyanya kuderedza chizvarwa che spatter. Mune laser welding, spatter inoderedzwa nekushandisa chaiyo yekudzivirira gasi, yakaringana yakatarisa chinzvimbo, uye akagadzirirwa paramita. STYLER's masisitimu akagadziridzwa kuti agadzire akachena, spatter-akaderedzwa welds akakosha pakuchengetedzeka kwepakiti.

9. Ndeapi metrics atinofanira kushandisa kusimbisa weld mhando mupakiti?

Kunze kwekutarisa kwekuona, makiyi ekusimbisa metrics anosanganisira:

Electrical Resistance/Conductivity: Kuyerwa pane imwe neimwe weld joint; kushomeka uye kunoenderana kuramba kwakakosha pakuita kwepakiti.

Dhonza / Peel Simba: Mechanical inoparadza kuyedza pamasampuli kuti ive nechokwadi chekubatanidza kutendeseka kunosangana nezvakatemwa.

Nugget Size / Seam Kupinda: Yakasimbiswa kuburikidza neyakachinjika-chikamu ongororo panguva yekukodzera maitiro.

Kugadzira Data Kudhirowa: Yese weld's paramita (ikozvino, nguva, simba) inorekodhwa ne STYLER midziyo yekuzara yekugadzira traceability.

10. Indasitiri iyi iri kuchinja sei welding kuti ishandiswe pakugadzira mapaketi matsva akadai seCTC (Cell-to-Chassis) kana mapaketi makuru ekuvaka?

Aya madhizaini anoda welding maitiro anogadzira akasimba, akavimbika emagetsi uye dzimwe nguva magadzirirwo ekubatanidza pamwero mukuru. Vanosundidzira zvinodiwa zvekudzika kwe weld, kumhanya, uye kuenderana. Yepamusoro-Simba Laser Welders ari kuwedzera kushandiswa kune refu seam welds pamapaketi akavharirwa uye akaumbwa mabhazi. STYLER iri kumberi, ichigadzira zvigadziriso zvine simba rinodiwa, kunyatsojeka, uye kugona kusangana neaya anotevera-chizvarwa pack musangano matambudziko.

Mhedziso

Battery pack welding chirango chakanangana nekugadzira akakwana kubatanidza magetsi mukati megungano rakachengeteka uye rakavimbika. Kudyidzana kwakakodzera uye sarudzo yetekinoroji ndiyo inogadzirisa kubudirira kwechigadzirwa chako.

Pa STYLER, tinopa mhinduro dzakanangwa dzekubatanidza bhatiri pack. Kubva pakudzikama kwepamusoro-soro kweTransistor-based Resistance Spot Welders uye iko kuchinjika kweLaser Welding Systems yedu kune yakanyatsobatanidzwa otomatiki yeBattery Pack Assembly Lines yedu, isu takazvipira kupa simba kugadzira kwako nekuvimbika, hunyanzvi, uye kugona.

Wagadzirira kukwirisa bhatiri rako pack welding process? Bata iyo STYLER nyanzvi timu nhasi kuti ubvunze.

Nguva yekutumira: Zvita-11-2025