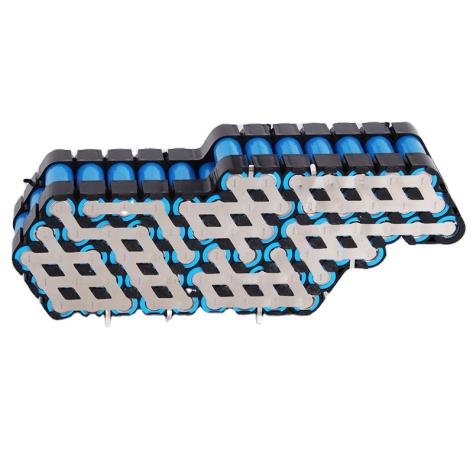

Mukugadzira lithium-ion bhatiri paki, kuita kwewelding kunokanganisa zvakananga conductivity, kuchengetedzeka, uye kuenderana kweinotevera bhatiri paki.Resistance spot weldinguyelaser welding, semaitiro makuru, imwe neimwe ine hunhu hwakasiyana, huchiita kuti ive yakakodzera kune akasiyana bhatiri zvinhu uye zvimiro zvematanho.

Resistance spot welding: Iyo nzira inosarudzirwa yewelding nickel sheets

Resistance spot welding inoshandisa kupisa kwekudzivirira kunoitwa neazvino kupfuura nepamashiti nickel kugadzira chisungo chakasimba chesimbi. Uku kupisa kwakanyanya uye kukurumidza kukwenenzverwa kunoita kuti ive yakanaka kune welding zvinhu senge nickel yakachena kana nickel ribhoni, inowanzoshandiswa mumabhatiri e-lithium-ion. Mabhenefiti ayo ari mukudhura-kushanda uye maitiro akakura, zvichiita kuti ive sarudzo yakavimbika yekukwirisa-vhoriyamu welding yebhatiri cell tabo uye majoini.

(Chikwereti: styler Images)

(Chikwereti: styler Images)

Laser welding: Iyo chaiyo nzira yewelding aluminium uye zvakakora zvinhu

Kana welding aluminum casings, aruminiyamu zvibatanidza, kana zvakakora zvimiro zvikamu, laser welding inoratidza zvayakanakira zvayakasiyana. Iyo laser beam yakanyanyisa simba density inoibvumira kubata yakakora aluminium busbar, kuwana yakadzika yekupinda welds uye kugadzira aesthetically inonakidza, airtight welds. Yakanakira kujoinha zvinhu zvealuminium mumabhatiri module uye mapaketi.

(Chikwereti: styler Images)

Yakazara-maitiro ekugadzira mutsara dhizaini kubva kune sero kuenda kune paki

Iyo yakazara lithium bhatiri yekugadzira mutsara inowanzobatanidza akawanda maitiro. Kubva pane yako chaiyo (nickel / aluminium / mhangura) uye bhatiri pack chimiro, tinogona kubatanidza matanho akadai sesero kuronga uye busbar welding, kubva kune rimwe nerimwe maseru kusvika kupedzisa bhatiri packs, kugadzira akagadziridzwa uye anochinjika ekugadzira zvigadziriso zvinoenzanisa kushanda zvakanaka, mutengo, uye kuita.

Mukugadzira bhatiri, hapana imwe-saizi-inokodzera-yese welding mhinduro. Mhando dzakasiyana dzebhatiri dzinowanzoda chaiwo maitirwo ewelding. Isu tinonzwisisa izvi uye takazvipira kupa huwandu hwakasiyana hwepamusoro welding michina yekukubatsira iwe kuwana yakanakisa sarudzo. Pa Styler, tinopa zvinopfuura midziyo chete; isu tinopa nzira yemaitiro yakarongedzwa kune zvaunoda. Taura nesu uye ngatishandisei yakanyatsokodzera welding tekinoroji kuchengetedza bhatiri rako.

Want to upgrade your technology? Let’s talk. Visiting our website http://www.styler.com.cn , just email us sales2@styler.com.cn and contact via +86 15975229945.

Nguva yekutumira: Oct-15-2025