Products

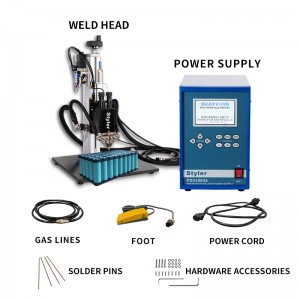

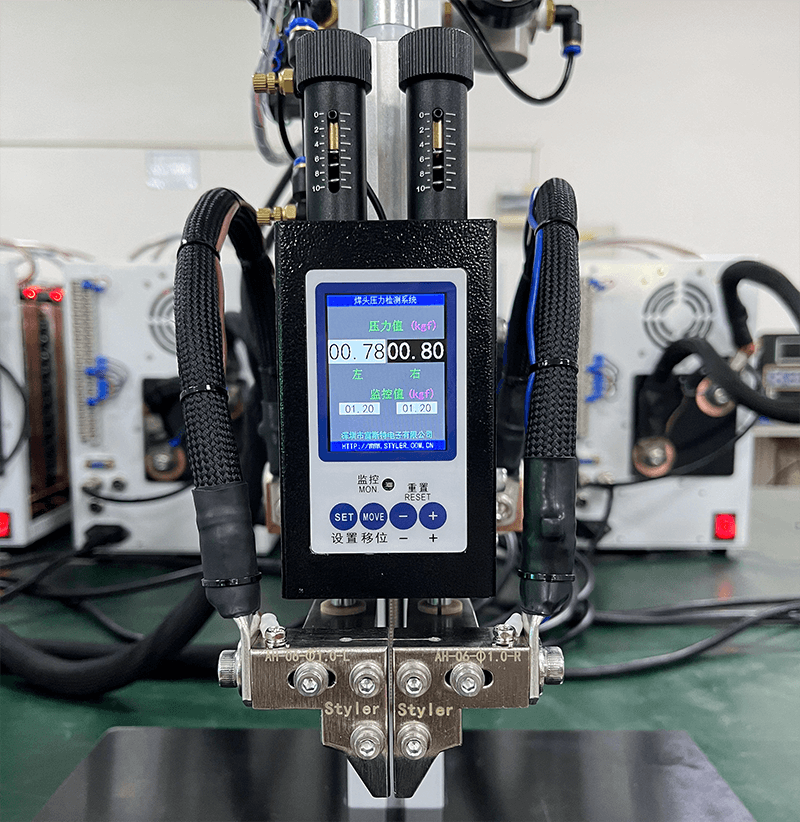

PDC6000A Spot Welding Machine

Product Features

Yekutanga inogara iripo, inogara voltage uye hybrid control mode inogamuchirwa kuti ive nechokwadi chekusiyana kwewelding process.

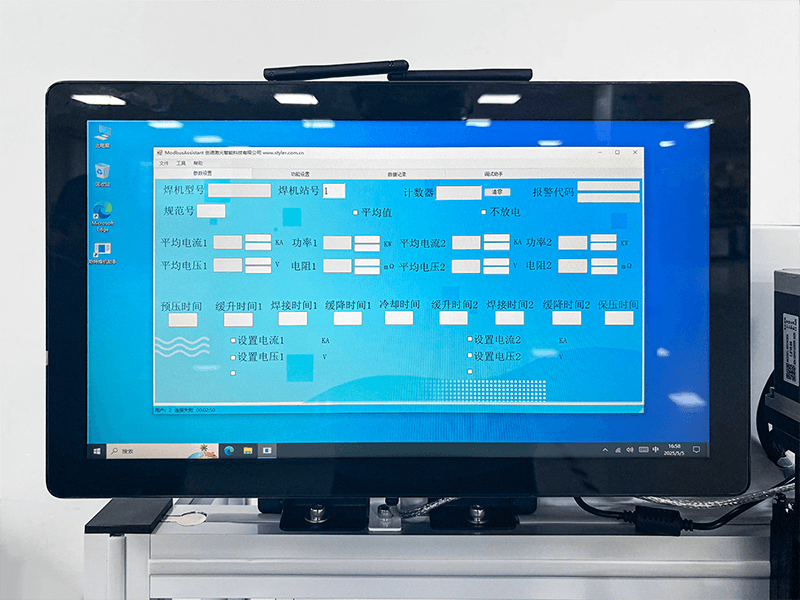

Hombe LCD skrini, iyo inogona kuratidza welding ikozvino, simba uye voltage pakati pemagetsi, pamwe nekubata kuramba.

Yakavakwa-mukati yekuona basa: pamberi peiyo yakasarudzika simba-pa, yekuona ikozvino inogona kushandiswa kusimbisa kuvepo kweiyo workpiece uye chimiro cheiyo workpiece.

Simba remagetsi uye maviri welding misoro inogona kushanda panguva imwe chete.

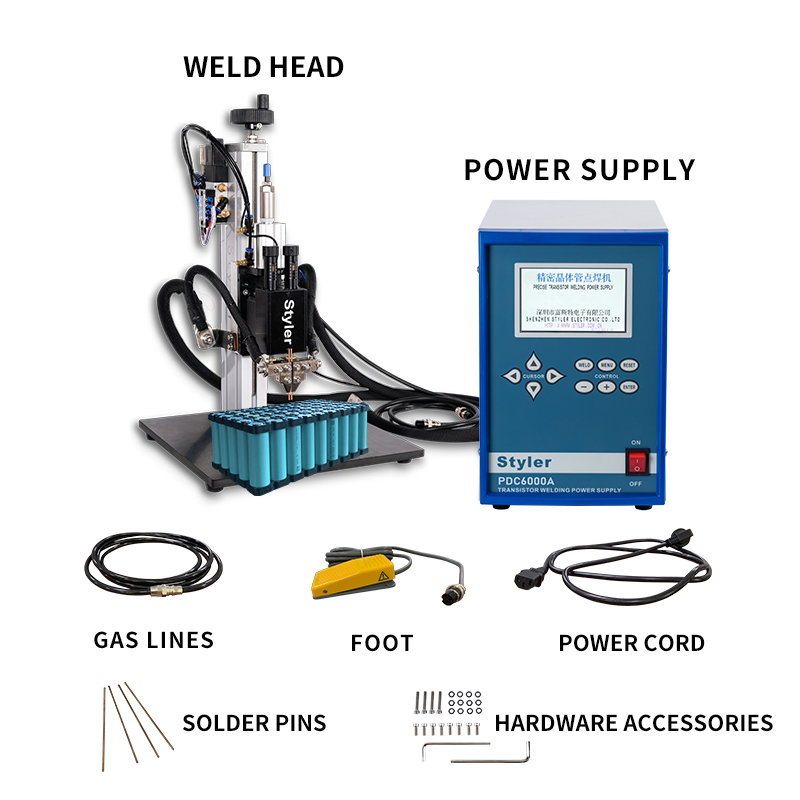

Iwo chaiwo welding paramita anogona kubuda kuburikidza neRS-485 serial port.

Inogona kushandura 32 mapoka esimba zvisina tsarukano kuburikidza nekunze madoko.

Yakazara yekupinza uye inobuda masaini, ayo anogona kushandiswa pamwe chete neakakwira degree re automation. Inogona kugadzirisa kure uye kufonera paramita kuburikidza neModbus RTU protocol.

Product Application

Inogona weld akasiyana akakosha zvinhu, kunyanya akakodzera kubatanidza simbi isina tsvina, mhangura, aruminiyamu, nickel, titanium, magnesium, molybdenum, tantalum, niobium, sirivheri, platinum, zirconium, uranium, beryllium, lead uye alloys avo. Zvishandiso zvinosanganisira micromotor terminals uye waya enamelled, plug-in components, mabhatiri, optoelectronics, tambo, piezoelectric crystals, sensitive components and sensors, capacitors nezvimwe zvinhu zvemagetsi, midziyo yekurapa, marudzi ese emagetsi ane macoil madiki anoda kusungirirwa zvakananga ne enamelled tambo, ma microwelding uye mamwe mawaya anogonesa anogona kusangana nemimwe tambo yewelding. process zvinodiwa.

Product Details

Parameter hunhu

| Device parameters | |||||

| MODEL | PDC10000A | PDC6000A | PDC4000A | ||

| MAX CURR | 10000A | 6000A | 2000A | ||

| MAX SIMBA | 800W | 500W | 300W | ||

| TYPE | STD | STD | STD | ||

| MAX VOLT | 30V | ||||

| INPUT | chikamu chimwe chete 100 ~ 120VAC kana chikamu chimwe chete200 ~ 240VAC 50/60Hz | ||||

| ZVIDONGO | .comst, curr;2 .const, volt;3 .const. musanganiswa wecurr uye volt;4 .const power;5 .const .curr uye simba musanganiswa | ||||

| NGUVA | kumanikidzwa kuonana nguva: 0000 ~ 2999ms kuramba pre-kuonekwa welding nguva: 0 .00 ~ 1 .00ms pre-yekuona nguva: 2ms (yakagadziriswa) nguva yekukwira: 0 .00 ~ 20 .0ms kushorwa pre-kuonekwa 1,2 welding nguva: 0 .00 ~ 99 .9ms kunonoka nguva: 0 .00 ~ 20 .0ms kutonhora nguva: 0 .00 ~ 9 .99ms kubata nguva: 000 ~ 999ms | ||||

| SETTINGS

| 0.00~9.99KA | 0.00~6.00KA | 0.00 ~ 4.00KA | ||

| 0.00~9.99v | |||||

| 0.00 ~ 99.9KW | |||||

| 0.00~9.99KA | |||||

| 0.00~9.99V | |||||

| 0.00 ~ 99.9KW | |||||

| 00.0~9.99MΩ | |||||

| CURR RG | 205(W)×310(H)×446(D) | 205(W)×310(H)×446(D) | |||

| VOLT RG | 24KG | 18KG | 16KG | ||

Optional accessories

Kombuta (chaiyo-nguva yekutarisisa yemajoini ekutengesa, data inogona kutumirwa kuburikidza neRS485)

Wedzera kudzvanya sensor kune welding musoro (kudzvanywa kwezvisungo pamativi ese maviri kunogona kugadzikwa kuve kunoenderana, uye kudzvanywa panguva yewelding kunogona kutariswa)

Sei kusarudza isu

1. Isu tanga tichitarisa pamunda weiyo precision resistance welding kwemakore gumi nemaviri, uye tine hupfumi hwemaindasitiri.

2. Tine core tekinoroji uye yakasimba R & D kugona, uye tinogona kukudziridza mabasa emunhu zvinoenderana nezvinodiwa nevatengi

3. Tinogona kukupa iwe nehunyanzvi welding scheme dhizaini.

4. Zvigadzirwa zvedu uye masevhisi ane mukurumbira wakanaka.

5. Tinogona kupa zvigadzirwa zvinodhura zvakananga kubva kufekitari.

6. Tine huwandu hwakakwana hwemhando dzezvigadzirwa.

7. Tinogona kukupa iwe nehunyanzvi hwekutanga kutengesa uye mushure mekutengesa kubvunza mukati meawa makumi maviri nemana.