Muchina wekuisa welding unobatanidza zvinhu zviviri zvewelding (nickel sheet, bhatiri sero, chibatiso chebhatiri, nendiro yekudzivirira nezvimwewo) pamwe chete kuburikidza nemoto welding.Hunhu hwenzvimbo welding hunokanganisa zvakananga kuita kwese, goho, uye hupenyu hwebhatiri hwebhatiri pack.Kushata kwenzvimbo welding kunogona kukonzera njodzi yebhatiri pfupi dunhu.

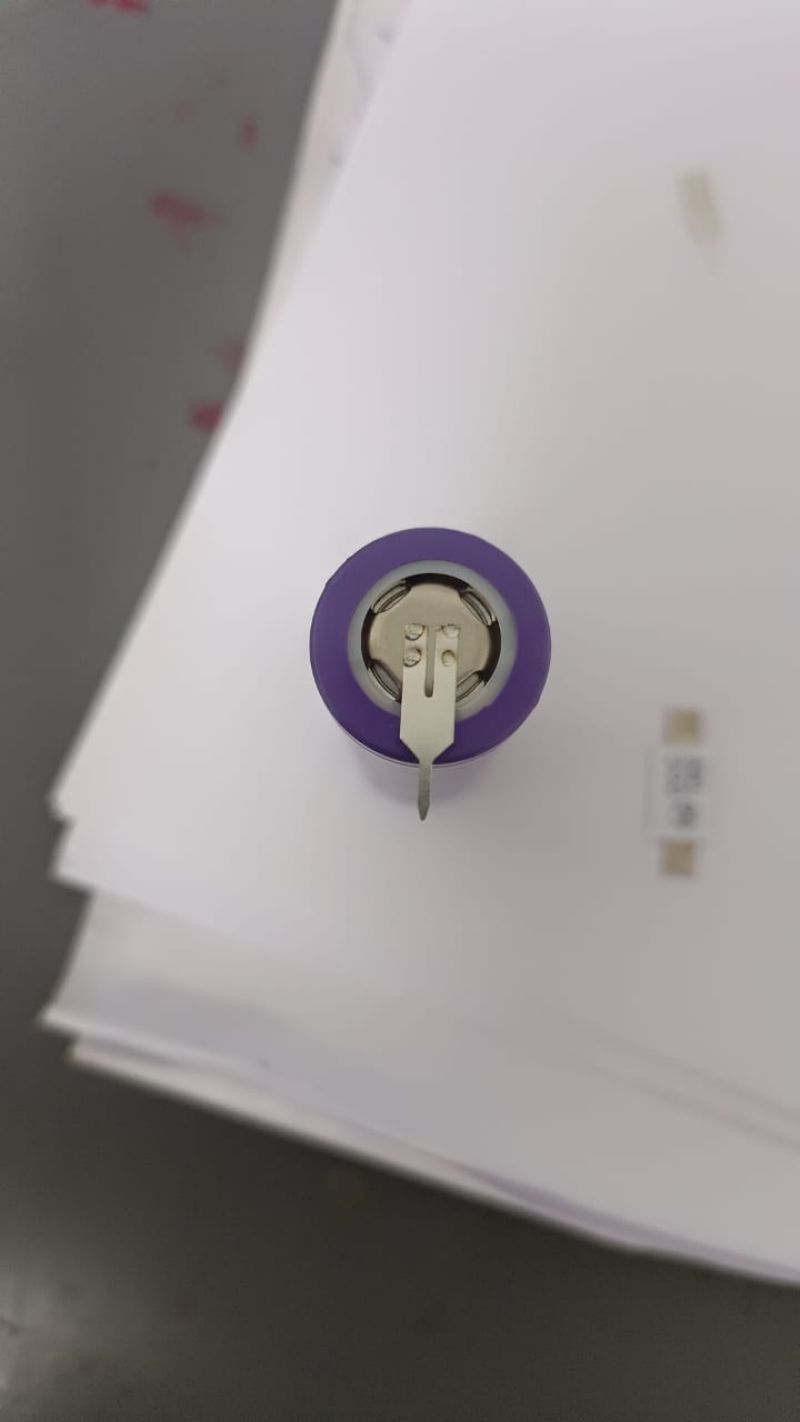

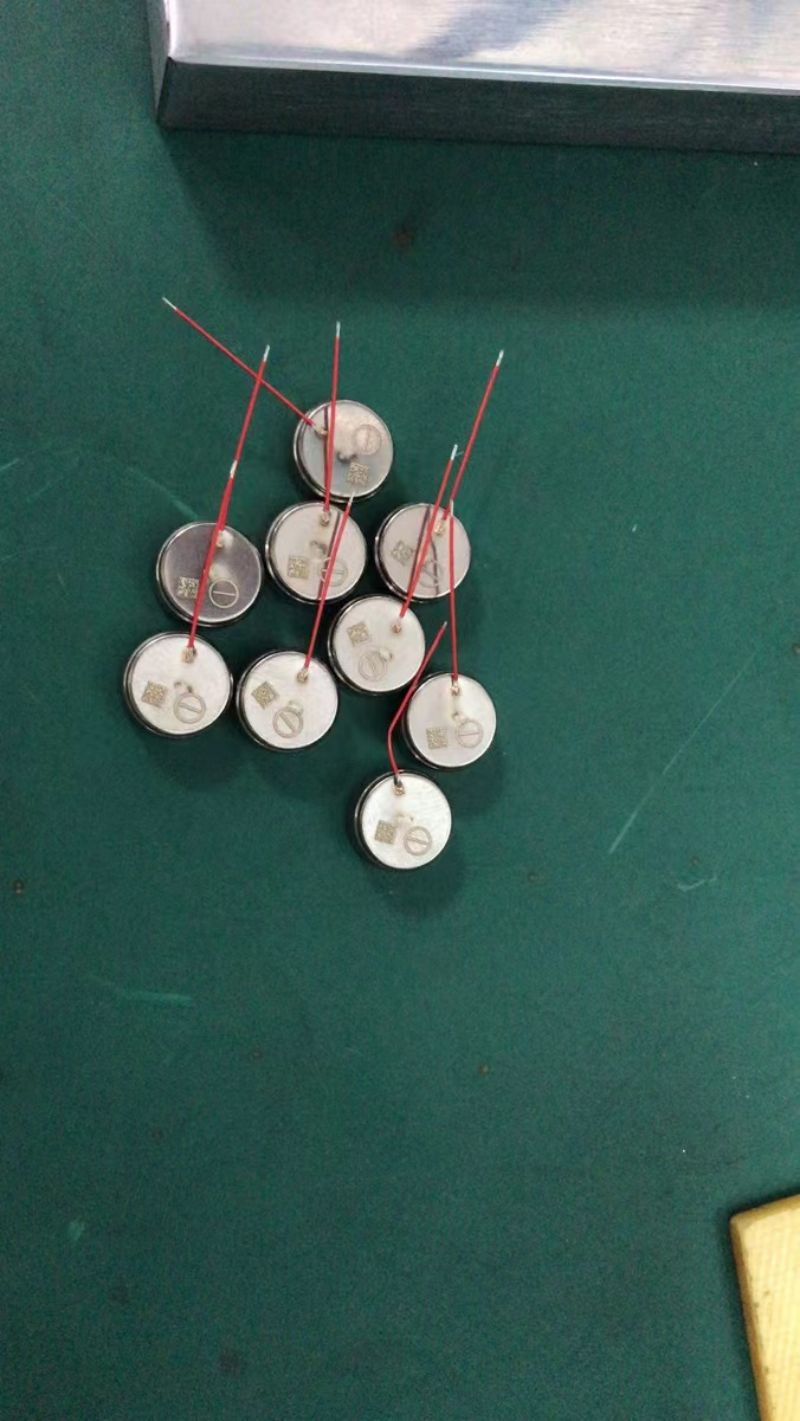

Heano mamwe masampuli ane defected welding mhedzisiro:

Battery spot welding muchina wakanyanya-kushanda uye wakanyanya-chaiyo welding midziyo, uye main process welding bhatiri inowanzo sanganisira pre-welding kugadzirira, welding process, uye post welding kurapwa.Muchikamu chekugadzirira kusati kwaita welding, zvakakosha kuisa bhatiri mumotofixture, inosarudza nzvimbo yewelding, uye gadzirisa ma parameters.Munguva yewelding process, bhatiri nzvimbo welding muchina unonyungudutsa simbi pakati pebhatiri electrodeskuburikidza nepamusoro-tembiricha uye yakakwirira-kudzvinyirira nzira, kuumba yakasimba welding point.Mune post welding nhanho, zvinodikanwa kubvisa bhatiri rakasungwa kubva pachigadziriso, uye kuita kuchenesa, kuyedza, uye zvimwe.kurapa kunoshanda.

Kupfuurirazve, zvimwe zvisaririra kana zvinosvibisa zvinogona zvakare kugadzirwa panguva yewelding process.Zvisaririra izvi zvinogona kunge zvine zvimwe zvinokanganisa zvakatipoteredza uye hutano hwevanhu.Semuyenzaniso, welding slag nesimbi oxides zvinogona kubuditswa munzvimbo ine exhaust gasi nemvura ine tsvina, zvichikanganisa kunaka kwemvura uye nharaunda yemhepo;Electrode powder inogona kuisa njodzi kune kufema system uye ganda revashandi.Nokudaro, zvakakosha kusarudza yakakodzeranzvimbo-welding midziyonokutiwelding chaiyoyebhatiri packs.

Izvo zvakati, nekushandisaStyler's transistor precision spot welding equipment, iyo welding process inogona kupedzwa munguva pfupi, ine kushoma welding kupisa kukanganiswa, uye pasina kupuruzira panguva yewelding process.Haisi yakakodzera chete kusungirirwa kwakanyatsonaka, asiwo kune zviduku, zvepamusoro-kushandaelectronic components, uye kuungana kwezvikamu zvidiki muindasitiri yemakina chaiwo.Semuyenzaniso, waya dzakatetepa, mabhatani mabhatiri, madiki madiki erelay, uye simbi foil.

Styler's precision welding equipment ine mashanu ekudzora modes: anogara aripo, anogara ari voltage, anogara aripo & anogara ari voltage musanganiswa, simba rinogara riripo, uye anogara aripo & anogara aripo emagetsi ekubatanidza modes, ayo anochinja nemaoko;32 seti dzesimba sarudzo dzinochinjika kuburikidza nekunze madoko;Iyo yekupinza & yekubuda chiratidzo maficha anowanikwa anoenderana neakazara-otomatiki kugadzira mutsara;Yakavakirwa-mukati yekuona basa: Pamberi pesimba repamutemo pa, panogona kuve neazvino yekuona kuratidza kuvepo uye chimiro cheiyo workpiece.

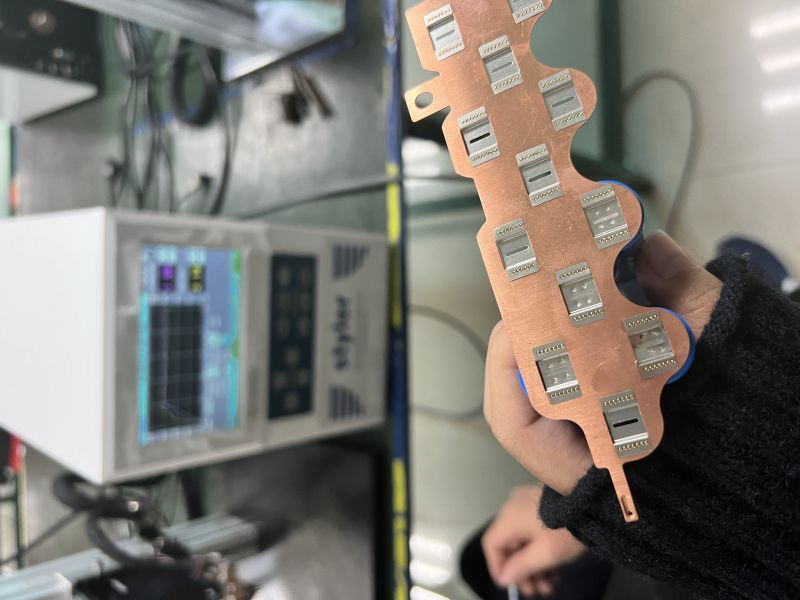

Izvi zvinotevera kuratidzwa kwebhatiri paki yakasungwa uchishandisa iyo Styler's PDC10000A transistor precision welding michina:

Kana iwe uchitsvaga welding muchina wakakodzera bhizinesi rako, ndapota taura nesu nhasi, kana tarisa chigadzirwa pejiPDC10000A transistor precision welding midziyo

Ruzivo rwakapihwa naStyler ("isu," "isu" kana "vedu") pa ("Saiti") ndeyezvinangwa zveruzivo chete.Ruzivo rwese paSaiti rwunopihwa mukutenda kwakanaka, zvisinei, isu hatiite chinomiririra kana waranti yechero mhando, kutaura kana kurehwa, maererano nekurongeka, kukwana, chokwadi, kuvimbika, kuwanikwa kana kuzara kwechero ruzivo paSiti.PASI PASI ZVINHU TICHAVA NEMUBADZO KWAURI PAKUNHU CHEKURASIKA KANA KUKATADZWA KWERUPI RWERUDZI rukapinzwa Nekuda kwekushandiswa kwesaiti KANA KUVIMBIRA PANE RUZIVO RINOPIWA PASAiti.KUSHANDISA KWAKO KWESATI UYE KUVIMBIRA KWAKO PANE RUZIVO CHESE PASATI KUNONYANYA PANYAYA YAKO PAMWE.

Nguva yekutumira: Sep-08-2023